Rubber Processing

At the heart of our rubber processing facility is a series of advanced extrusion lines, which allow us to produce hoses with precise tolerances and consistent quality. These lines are equipped with the latest in extrusion technology, including multi-layer extrusion and inline braiding machines, which allow us to produce hoses with a wide range of reinforcement options.

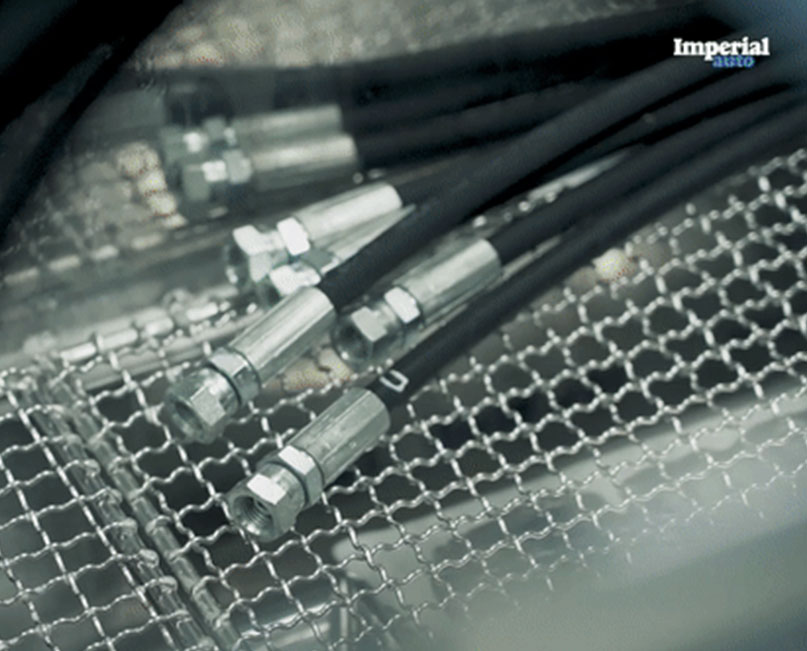

Assemblies

Our Facilities are equipped with the latest technology and machinery, allowing us to manufacture a wide range of hydraulic hose assemblies to suit a variety of applications. From braided hoses to spiral-wrapped and thermoplastic hoses, we have the expertise and capabilities to produce the perfect hose for your specific needs.

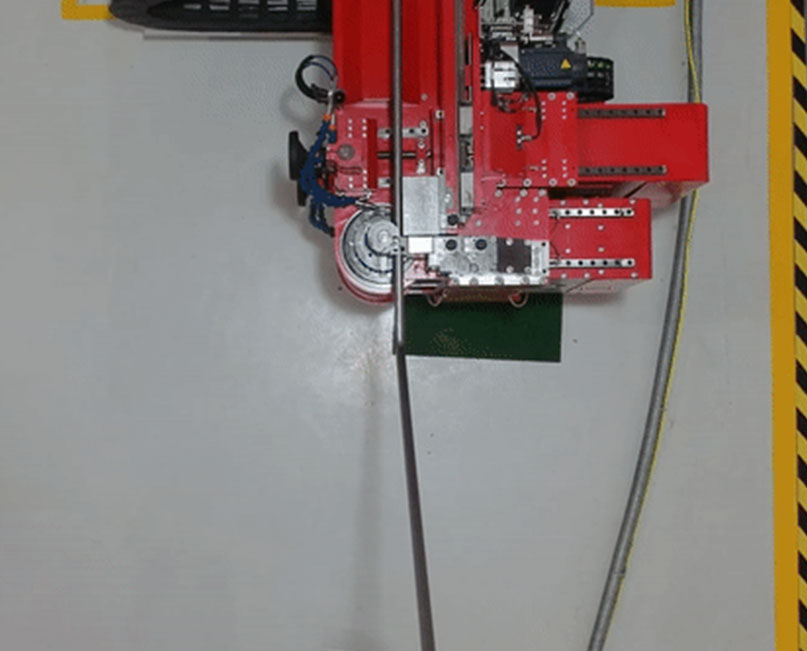

Tube Bending

Our state-of-the-art equipment allows us to bend tubes with precision and accuracy, ensuring that each product manufactured out of our facility meets the highest quality standards. From simple bends to complex shapes, we can handle projects of any size and difficulty level.

Hydraulic Cleanliness

We are committed to producing high-quality products that meet the highest standards of performance and reliability. This includes ensuring that our products are designed and built to meet the stringent requirements for hydraulic cleanliness. To achieve this, we have implemented a number of measures (NAS 6 Standards) to ensure that our products are free from contaminants that could potentially harm the performance and longevity of hydraulic systems.

Quality and Certification

At Imperial Auto, we are committed to producing high-quality products that meet the needs and expectations of our customers. We understand that quality is a top priority for our customers, and we strive to consistently deliver products that exceed industry standards.

To ensure that our products meet the highest quality standards, we have implemented a comprehensive quality management system at our manufacturing facility. This system is designed to identify and correct any potential issues before they affect the quality of our products.

In addition to our internal quality control measures, we also participate in third-party certification programs to demonstrate our commitment to quality. Some of the certifications can be found under the certifications tab of the website.

IAI Design Center

Our team of experienced designers is dedicated to creating innovative solutions that meet the unique needs of each and every one of our customers.

Our state-of-the-art design center is equipped with the latest tools and technology, allowing us to bring even the most complex designs to life. Whether you need a solution for a small passenger vehicle or a large industrial machine, we have the expertise and resources to deliver the perfect solution.

In addition to our custom design capabilities, we also offer a wide selection of standard fluid-transmission products that can be modified to meet your specific requirements. No matter what your needs may be, we are confident that we can find a solution that meets your performance and budget requirements.